Featured Services

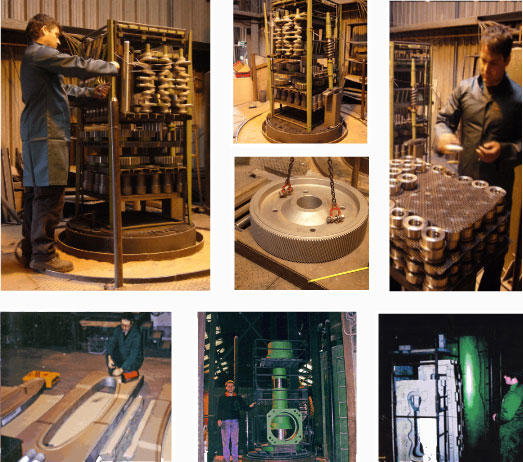

in the nitride hardening process.Nitride hardening provides steel

components with very high surface hardness whilst utilising a low

process temperature with slow cooling at cycle end.This results in

vastly increased wear resistance combined with zero distortion on

comple, finished components.

- Automotive – Competitive (F1) etc

- Gear & Power – Transmissions

- Construction – Drilling & Piling equipment

- Machine Tools – Component Parts

- Metal Forming – Dies & Moulds

Nitride hardening, Steel components, Wear resistance, Automotive, Gear & Power, Construction, Machine Tools, Metal Forming

As recognised World leading suppliers of metallic grinding media, we are pleased to advise the most suitable grade for any particular application.

Calculation of the most appropriate ball size and grading to achieve

maximum grinding efficiency is offered free of charge.

We supply four types of grinding media.

1. High Chrome Grinding Media

High chromium cast irons are used extensively for the production of

grinding balls from 15mm to 110mm diameter. Criteria for successful application is a combination of toughness to resist breakage and wear resistance for extended life. Inevitably this requires a compromise due

to the conflicting properties required to produce these criteria. Chemical specifications range from 2.0% to 3.0% Carbon, and 12% to 30% Chromium depending on media size and application, with secondary additions of molybdenum in some cases and almost all alloys are heat treated.

2. Forged Steel Grinding Media

Traditionally used in wet applications and in environments with extreme wear. Used extensively in the mining industry particularly for grinding ores.

We supply 3 main grades of high carbon forged steel in the size range 25mm – 150mm diameter.

Grade Hardness

- Longwear 300 (260 – 400BHN)

- Longwear 500 (450 – 550BHN)

- Longwear 700 (650 – 740BHN)

3. Chillard Extra Cylpebs

Longwear Chillard Extra is a modified variation of white cast iron where additional chromium is added to give an improved hardness level of 57-60 HRc. Due to greater specific surface area and improved bulk charge density it can be shown that in many applications cylpebs achieve a much greater grinding efficiency than an equivalent sized ball.

The unique production process allows for a consistent hardness level from surface to core leading to an even wear pattern in service.

4. Refurbished Grinding Media

For many years Longwear Limited have supplied refurbished grinding media to the cement and mineral processing industry both in the UK and overseas. Our refurbished quality is stringently tested before being graded and packed into new drums ready for supply back into the comminution industry.

Refurbished grinding media offers an extremely cost effective alternative to new media as well as the environmental benefits associated with the manufacture of new media.

Full guarantees are provided and samples can be submitted for approval prior to despatch.

Nickel-Chrome Alloy Heat Resistant Parts for Rotary Kilns and Coolers with operating temperatures up to 1200 degrees Centigrade.

- Cooler Grate Plates

- Satellite Cooler Liners

- Satellite Cooler Lifters

- Rotary Cooler Lifters

- Kiln Nose Rings

- Furnace & Kiln Furniture

- Entry Chutes

wear resistant parts and alloy castings in various alloys

and grinding media for the Mining, Quarrying and General

Engineering industry sectors.

We have the expertise to recommend the most suitable of

materials to give optimum performance in environments

requiring abrasive and/or impact resistance.

Alloy Castings

If you have specific criteria for your requirements, Longwear

Ltd can provide accurate alloy castings for many purposes.

Longwear Ltd can individually design bolted or boltless ball mill lining systems to suit every type of grinding application.

We have technical expertise to advise on the choice of liner profiles and alloy selection to achieve a cost effective and durable solution for optimum grinding performance.

The comprehensive range of alloys offered have been specially developed to achieve the maximum amount of wear resistance and the minimum of maintenance. Liners are guaranteed fit for purpose with a performance warantee relative to the operating conditions.

Feed Head Wall Liners

1st Chamber Shell Liners

Intermediate Diaphragm Assemblies

2nd Chamber Classifying Liners

Discharge Diaphragm Assemblies