As recognised World leading suppliers of metallic grinding media, we are pleased to advise the most suitable grade for any particular application.

Calculation of the most appropriate ball size and grading to achieve maximum grinding efficiency is offered free of charge.

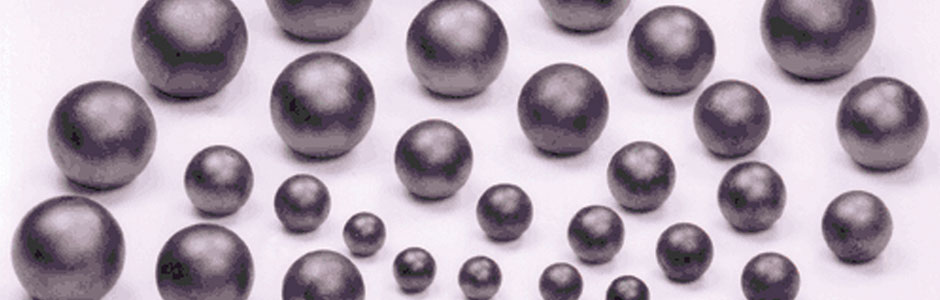

We supply four types of grinding media.

1. High Chrome Grinding Media

High chromium cast irons are used extensively for the production of grinding balls

from 15mm to 110mm diameter. Criteria for successful application is a combination

of toughness to resist breakage and wear resistance for extended life. Inevitably this

requires a compromise due to the conflicting properties required to produce these

criteria. Chemical specifications range from 2.0% to 3.0% Carbon, and 12% to 30%

Chromium depending on media size and application, with secondary additions of

molybdenum in some cases and almost all alloys are heat treated.

2. Forged Steel Grinding Media

Traditionally used in wet applications and in environments with extreme wear. Used

extensively in the mining industry particularly for grinding ores.

We supply 3 main grades of high carbon forged steel in the size range 25mm –

150mm diameter.

Grade Hardness

Longwear 300 (260 – 400BHN)

Longwear 500 (450 – 550BHN)

Longwear 700 (650 – 740BHN)

3. Chillard Extra Cylpebs

Longwear Chillard Extra is a modified variation of white cast iron where additional chromium is added to give an improved hardness level of 57-60 HRc. Due to greater specific surface area and improved bulk charge density it can be shown that in many applications cylpebs achieve a much greater grinding efficiency than an equivalent sized ball.

The unique production process allows for a consistent hardness level from surface to core leading to an even wear pattern in service.

4. Refurbished Grinding Media

For many years Longwear Limited have supplied refurbished grinding media to the cement and mineral processing industry both in the UK and overseas. Our refurbished quality is stringently tested before being graded and packed into new drums ready for supply back into the comminution industry.

Refurbished grinding media offers an extremely cost effective alternative to new media as well as the environmental benefits associated with the manufacture of new media.

Full guarantees are provided and samples can be submitted for approval prior to despatch.